.jpg)

.jpg)

Basalt Rebar – an Innovative Alternative to Steel and Fiberglass

Basalt rebar reinforcement stands out as a compelling substitute for traditional steel and fiberglass in reinforcing concrete structures. Derived from volcanic rock, basalt rebar surpasses steel in toughness and strength, boasting a higher tensile strength. What sets basalt rebar apart is its notably lighter weight compared to steel rebar, facilitating easier handling and significantly reducing shipping costs.

_edited.jpg)

Inherently resistant to alkali, rust, and acids, basalt rebar requires no special coating like fiberglass rods. Moisture penetration from concrete does not result in spalling. Furthermore, basalt rebar shares the same thermal coefficient expansion as concrete, enabling the construction of thinner, lighter panels and decks. This characteristic reduces the thickness and spacing between the rods and the concrete surface, allowing for a more flexible and efficient design. Smaller rods permit more critical spacing and intricate designs.

Basalt rebar's versatility extends to ease of cutting, as it can be easily trimmed to the desired length using conventional tools. Moreover, it does not conduct electricity or induce fields when exposed to RF energy, making it ideal for applications in MRI or data buildings.

Especially well-suited for marine environments and chemical plants where corrosion is an ongoing concern, basalt rebar reinforcement excels in durability and resilience.

Available in various diameters—4mm, 6mm, 8mm, 10mm, 12mm, and 25mm—basalt rebar offers flexibility in construction. Diameters ranging from 4mm to 12mm are available in 100m coils or cut lengths, while those from 14mm to 25mm are packaged in 10-foot cut lengths.

During trials, slabs reinforced with basalt rebar were closely monitored for flexural strength, shear strength, and pull-out resistance. Impressively, the basalt rebar consistently outperformed steel-reinforced slabs.

In terms of shear strength, the basalt rebar slabs demonstrated superior performance under applied loads compared to their steel-reinforced counterparts. The basalt rebar reinforced concrete achieved a maximum strength of 141.5kN with classic concrete and 106.1kN with low carbon concrete. In comparison, steel-reinforced concrete reached 110.1kN and 97.5kN, respectively, highlighting the remarkable strength and resilience of basalt rebar in practical applications.

.jpg)

SWIMMING POOL CONSTRUCTION WITH BASALT REBAR. ALSO USED IN ARCHEOLOGICAL SITES WITH NATURAL HYDRAULIC LIME.

.jpg)

.jpg)

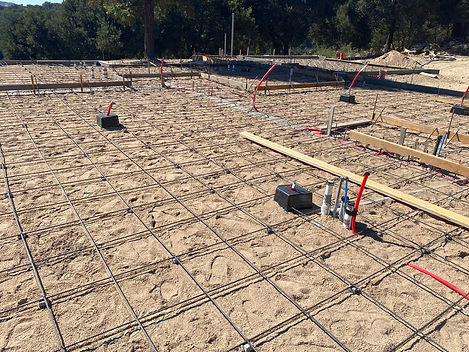

BASALT REBAR IN RESIDENTIAL FOUNDATION CONSTRUCTION

Historic Fortifications Repaired with Basalt Rebar

Skanska with National Highways puts basalt rebar to the test Testing basalt rebar in combination with traditional and low carbon concrete, comparing with steel in the same conditions. Skanska constructed a temporary works access road using various concrete slab combinations.